- Home EN

- Specialist Areas

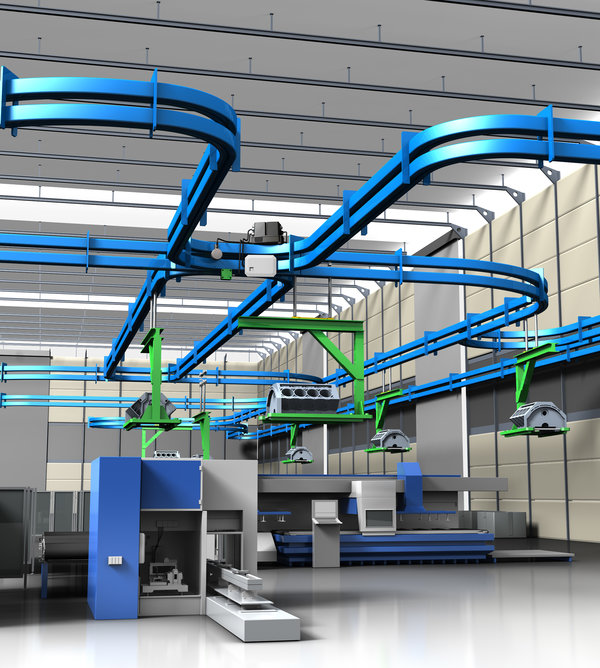

- Power & Free conveyor systems

Decentralised automation for Power & Free conveyor facilities

Power & Free conveyor facilities are sturdy and reliable material flow systems with a high flexibility for the user. This freedom and flexibility are achieved at the planning and automation phases with the decentralised Power & Free Controller. The Power & Free Controller can be installed at any location within the machine close to the actuator, and it will control the actuator of the corresponding load trolley. Installation structures of up to 300 metres are reached via integrated energy cables and databus wires, supporting plant manufacturers in system planning, installation and supplementary plant extensions. The integrated energy management will be of great advantage to the system user regarding system operation, service and maintenance measures and high equipment availability.

Our commitment:

- Reduced project duration

- Flexible facility structure and high equipment availability

- Minimum installation costs

- Increased equipment availability for the user

- Minimum service times for the user

- Optimised energy and resource efficiency

Your advantage:

- Retention of the standard controller inside the control cabinet

- Short planning and project times

- Feedback- free copying of projected equipment components

- Easy equipment extension with modular system

- High equipment availability for the user. Minimum facility downtimes during service and maintenance

- Standardisation of facility sections and components

- Clear and intuitive facility modules

- Short installation and start-up times

- Minimisation of connection faults

- Reduction of control cabinet surface areas

- Built-in energy saving mode. Actuator energy saving of up to 30%

Discover the best solution for you